Gl Engineering & Construction Pte Ltd

About Us

Baker Engineering Pte. Ltd. was incorporated in May 2013 as a wholly-owned subsidiary of SGX mainboard listed Baker Technology Limited.

Baker Engineering's main focus is on the design, engineering and construction of mobile offshore units including liftboats, mobile offshore production units and self-elevating units for the offshore marine oil & gas sector. Apart from that, it has a sub-division that provides steel fabrication and piping work for the oil & gas, marine, mining and the land construction industries.

BEL Design Pte. Ltd. was incorporated in January 2014 as a wholly-owned subsidiary of Baker Engineering to develop and own mobile offshore units designs.

Baker Engineering operates out of three waterfront shipyards in Singapore, each equipped with open production facilities, office buildings, workshops and warehouses. Waterfront advantage provides our customers with an option to transport final products by sea. The onsite warehouse is equipped with a live Enterprise Resource Planning (ERP) system fully integrated with procurement division for inventory enhanced traceability.

Please click on the links below to find out more about our quality policies.

- OH&S Policy Statement.

- Environmental Policy Statement

- Quality Policy Statement

Vision & Mission

"To be a leading shipyard specializing in the design, engineering, development and construction of mobile offshore units for the offshore marine and oil & gas sector, offering advanced products and innovative solutions for the diverse and specific needs of our global customers."

Mr. Tan Wee Lee, Managing Director.

Strategy

Our strategy emphasize the importance of advanced engineering & construction techniques, a highly qualified management and staff, a flexible organization enabling close co-operation between cross disciplines, and to our clients a shipyard with the best attitude. All supported by a sound financial base.

BEPL Management.

On Occupational Health and Safety

At Baker Engineering, Safety is a way of life.

Baker Engineering places top priority on occupational safety and health. We believe in active engagement from our employees across all levels in cultivating a positive safety culture that forms a basis for our business activities. We place great emphasis on health and safety training, awareness, procedures and general education. We also aim to ingrain safety into each and every employee and subcontractor working with us.

Baker Engineering was certified to comply with the Occupational Health and Safety Management System "OHSAS 18001:2007" on 1st June 2015. Baker Engineering is also certified with the bizSAFE Star in June 2015. By incorporating the bizSAFE programme into its WSH culture, the Company has managed to improve its WSH standards and reduce downtime.

On Care for our Environment

Baker Engineering's Environmental Management System (EMS) was certified to ISO 14001:2015 on 4th May 2017 by DNV-GL. The certification is valid for the design, engineering, procurement and construction of Self Elevating Units and Liftboats for the offshore, oil & gas and wind farm industries. Achieving ISO 14001:2015 certification is yet another testament to our dedication towards delivering products and services with a high standard of quality, whilst the accreditation provides assurance to company management and employees as well as external stakeholders that environmental impact is being measured and improved.

To protect and conserve the environment, Baker Engineering have risk assessments and procedures in place for the identification, handling and disposal of both hazardous and non-hazardous material. Scrap material which can be reused are also set aside for future use.

On Implementing the best corporate practices in the way we conduct our business

Maintaining and promoting the highest ethical, moral and legal standards in its internal and external operations are at the core of Baker Engineering's business philosophy. In addition, Baker Engineering believes in contributing in a positive manner to communities in which it operates and support a number of activities in this regard.

Baker Engineering actively supports the activities of its parent company Baker Technology which has a long-standing tradition of contributing to local communities, and works closely with different charitable organisations to contribute to society and provide assistance to those who are less fortunate

Queries from the media or any investor relations queries are advised to contact the following individual at Baker Technology Limited, or to email investor relations:

Lorraine Lee

Tel: 6262 1380

Email: investor_relations@bakertech.com.sg

Our Services

- Legacy

- Design

- Vessel Types

Baker Engineering Pte. Ltd. was set up in May of 2013. Since late 1970s, the management has been involved with the rigs building industry, where the current shareholders at Baker Engineering were also the founder and manager of a renowned shipyard which built 43 units of jack up drilling rigs of designs of 350 and 400 feet water depths, and semi-submersible drilling rigs.

Albeit a young entity, the team at Baker Engineering performed a timely delivery of its state-of-the-art DP2 Liftboat "Blue Titanium" where its performance serve as a testament to Baker Engineering's exemplary design & build capability.

At Baker Engineering, our team of engineers work relentlessly, making us one of the experienced companies that has sharpened their saw in disciplines of engineering, production and QA/QC that ensures immaculate executions of the designing and engineering work.

Working alongside Baker Engineering are our in-house designers under BEL Design Pte. Ltd., a wholly-owned subsidiary of Baker Engineering Pte. Ltd. that specializes in creating sustainable designs through the innovation of technology and smart engineering, while keeping in line with the latest standards and requirements set forth by the industry and its regulators for Mobile Offshore Units.

When it comes to detailed and construction engineering, Baker Engineering kept true to its roots by applying our design principles of being safe, reliable, and easy to operate.

With clients' preferences as our priority, we are able to provide bespoke vessel designs as well as working with other design houses to deliver the most optimum solution. We are dedicated to maintain high level of expertise in project management and construction that includes safety, quality and care for the environment.

At Baker Engineering, we provide engineering and construction services ranging from a broad spectrum of Mobile Offshore Units.

- Repairs & Maintenance

- Upgrades

- Conversions

- Preservation & Protection

Baker Engineering provides trained and experienced field staff and supervisors to plan and execute rig repair programs or provide highly experienced field mechanics and technicians capable of troubleshooting and performing field repairs on all types and sizes of offshore rig equipment, including heavy mechanical repair.

We offer comprehensive services for all aspects of repairs, including:

- Inspection, analysis and structural design

- Project management

- Offshore surveying, installation and commissioning

- Surface preparation, coating removal and recoating

- Hull painting, plating, piping and structural repairs and replacement

- Industrial painting

- Repairs to spud can and legs, shock pads and coamings replacements

- Repairs and refurbishment of accommodation quarters

- Repair/replacement of shale shaker, leg racings, jacking unit, raw water tower

If in-situ repairs really isn't possible, we can take components to our fully equipped workshops.

Baker Engineering provides the following services for rigs upgrades:

- Life enhancements & Extensions

- Reactivation of old rigs

- Conversions including replacement of existing hydraulic to electrical jacking systems

- Introduction of helper jacks for existing jacking systems

Baker Engineering provides the following services for conversion:

- Feasibility studies based on Global Structural Analysis

- General & Structural Arrangement Drawings

- Full engineering work scope

Baker Engineering provides the following services for Rig Preservation & Protection:

- Corrosion Protection

- Humidity Control

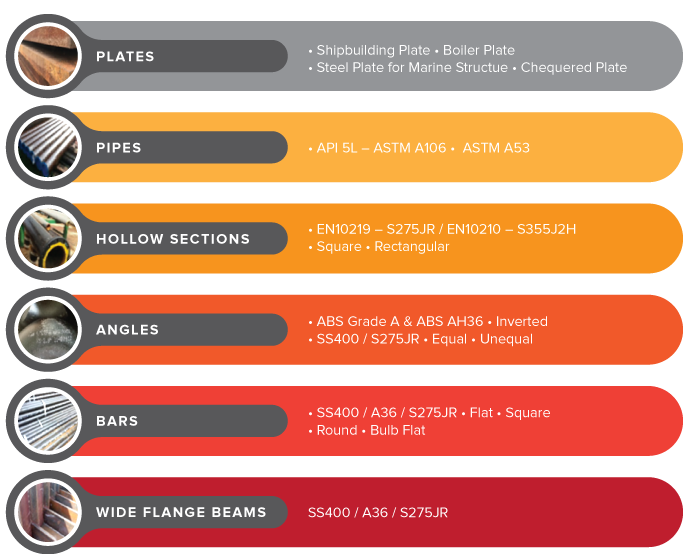

- Fabrication

- Material

- Critical Components

- Custom Design

We fabricate modern, complex and intricate steel structures and work tirelessly to produce exceptional results for each and every customer and projects. Supported by an in-house design & engineering team, as well as quality assurance & control, and production teams, we provide fabrication solutions with high quality workmanship, on time and at competitive rates.

We are dedicated to maintain a high level of expertise in project management and construction that includes safety, quality and care for the environment. The products we deliver adhere to the exacting requirements and tolerance standards imposed by designers and manufacturers.

Baker Engineering pushes designs to meet parameters through the use of high tensile steel of up to 120 ksi. Each material is carefully recorded into the company's ERP system which is fully integrated with the warehousing division for procedure and inventory enhanced trace-ability.

Combining the experiences and expertise, Baker Engineering provides bespoke services with a focus on error prevention through design consultancy for complicated/sophisticated steel structures, and provide alternative design(s) and building solution(s).

All fabrication work are completed in accordance with the appropriate standards, adopted to define the work procedures. The company provides for clients' fabrication needs with the following steel structural and welding codes:

- AWS D1.1/D1.1M Structural Welding Code – Steel

- ASME BPVC Section IX Welding, Brazing, and Fusing Qualifications

- ISO 15614-1 Specification & Qualification of Welding Procedures for Metallic Materials

- AS 4100 Steel Structures

- AS/NZS 1554.1 Structural Steel Welding

- Marine Classification Rules, e.g. ABS, DNV-GL, LR & BV

- Jack casings

- Welded racks and chords

- Flame cut Racks

- Rack and Chords

- Boat-landings

- Cantilevers

- Structured Tubular/Truss Legs for Jack Ups

- Raw Water Towers

- Bracings

- Support structures

- Cofferdams

- Living Quarters

- Lifting Frames

- Pipe lifting/Alignment/Handling Frames

- Hang-off structures, e.g. Pulling Heads

- Steel Towers/Chimneys

- Steel Manifolds

- Gangways

- Crash Frames

Projects

-

A3001 – Blue Titanium

Designed and built by Baker Engineering Pte. Ltd., Project A3001 was completed in April 2018. Named Blue titanium, she is a…

-

A3002 – Accommodation Module

Designed and built by Baker Engineering Pte. Ltd., Project A3002, also known as Additional Living Quarters ("ALQ") was completed in…

-

Upcoming Project

Watch this space for our latest projects

News

-

26th February, 2021

Baker Technology Limited, Full Yearly Results, Financial Statements and Related Announcements (Full Yearly Results)

-

28th February, 2020

Baker Technology Limited, Full Yearly Results, Financial Statements and Related Announcements (Full Yearly Results)

-

06th August, 2019

Baker Technology Limited, Second Quarter and/or Half Yearly Results, Financial Statements and Related Announcements (Second Quarter and/or Half Yearly Results)

-

06th May, 2019

Baker Technology Limited, First Quarter Results, Financial Statements and Related Announcements (First Quarter Results, Financial Statement)

-

26th June, 2018

Baker Technology Limited, Third Quarter Results

-

30th July, 2015

Baker Technology Limited, Second Quarter Results

-

23rd April, 2015

Baker Technology Limited, First Quarter Results

-

26th February, 2015

Baker Technology Limited, Full Year Results

-

16th February, 2015

The Keel Lay Ceremony of Hull No: A3001, a BEL Design Class 320 Liftboat (BEL320-4R200S Liftboat) was held at Baker Engineering's yard in Singapore on 16 February 2015.

-

07th November, 2014

The Strike Steel Ceremony marking the construction of the BEL320-4R200S Liftboat (Hull No: A3001) was held at Baker Engineering's yard…

-

29th October, 2014

Baker Technology Limited Third Quarter Results, Financial Statement (Third Quarter Results, Financial Statement ), and Related Announcement ( Media Release. )

-

26th August, 2014

ABS Pacific (Singapore) has been appointed by Baker Engineering on 26th August 2014 to provide the plan approval and survey of Baker Engineering's BEL320-4R200S Liftboat which is under construction in Baker Engineering's shipyard in Singapore.

-

31st July, 2014

Baker Engineering's Quality Management System was certified to ISO9001: 2015 on 2nd June 2016 by DNV GL. The certification is valid for the design, engineering, procurement and construction of Self Elevating Units and Liftboats for the offshore, oil & gas and wind farm industries.

-

31st July, 2014

Baker Technology Limited ("Baker Tech"), 2Q & 1H 2014 Results Briefing. Key highlights include the completion of the design of a state- of-the-art Liftboat, the Class 320 (BEL320-4R200S).

-

31st July, 2014

Baker Engineering Latest News: Baker Engineering will be commencing the construction of liftboats

-

17th June, 2013

To view past news, please click on the link below. Baker Technology News Archive

Posted by: deidraporticeswa.blogspot.com

Source: https://www.bakerengineering.com.sg/

Posting Komentar untuk "Gl Engineering & Construction Pte Ltd"